U9-S04. Microfluidics and microwave-assisted production of nanoparticles

Microfluidics and microwave-assisted production of nanoparticles

Conventional batch reactors may suffer from limitations due to the inefficient heat and mass transfer that makes it very difficult to achieve an accurate control on the synthesis conditions. This has a direct effect on key aspects such as reproducibility, selectivity and scalability. In fact, one of the bottlenecks in the development of Nanotechnology lies in the lack of precise synthesis methods capable of a scaled up production.

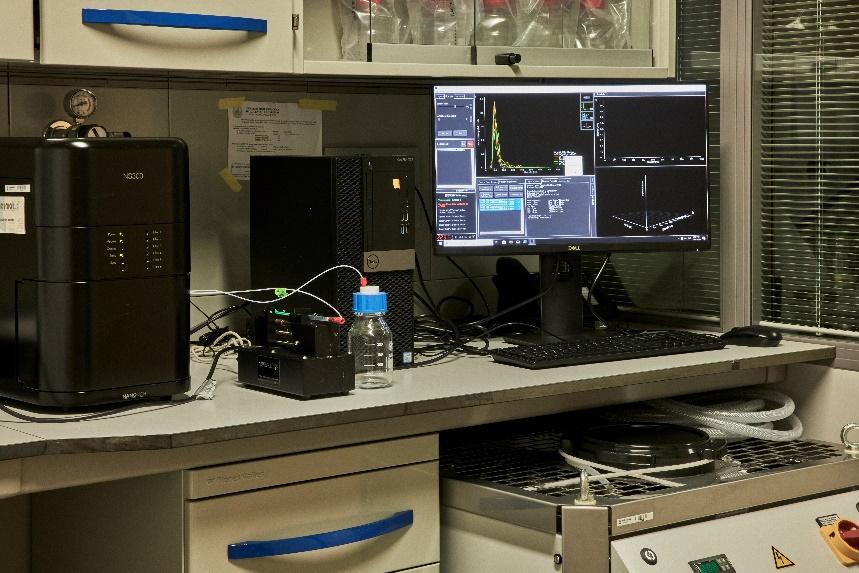

Continuous flow reactors based on microfluidic principles offer potential solutions to the aforementioned concerns. The exquisite control afforded by microfluidic reactors enables continuous production of nanomaterials with targeted sizes, shapes and composition. Moreover, the combination with microwave reactors can accelerate the stabilization of metastable phase due to the fast and selective heating supplied by this electromagnetic irradiation.

Customer benefits

The customer can benefit from the Unit´s expertise on the design of versatile microfluidic platforms to produce a broad library of nanostructures in a continuous fashion, often with a strong reduction of processing times with respect to the corresponding batch process. The Unit also offers unprecedented flexibility in terms of tuning the reaction atmosphere. Access to microwave reactors to perform fast heating reactions will be another asset to optimize specific synthesis and/or reactions in liquid media.

Target customer

Pharmaceutical companies, material suppliers, research groups pursuing a controlled and potentially scalable production of materials.

Additional information

Selected References:

- R. Quirós-Ovies, et al., Microwave-driven exfoliation of bulk 2H-MoS2 after acetonitrile pre-wetting produces large-area ultrathin flakes with exceptionally high yield, ACS Nano, 17, 5984-93 (2023).

- Manno, R., RanjaN, P., Sebastian, V., Mallada, R., Irusta, S., Upendra K. Sharma, U.K., Van der Eycken E.V., Santamaria, J., Continuous Microwave-Assisted Synthesis of Silver Nanoclusters Confined in Mesoporous SBA-15: Application in Alkyne Cyclizations. Chem. Mat. 32, 7, 2874–2883, (2020).