Researchers of Unit 5 of NANBIOSIS, in collaboration with colleagues from the University of Montpellier, have laid the groundwork for faster advances in 3D printing for regenerative medicine by creating a system of ink and matrices that offers a solid basis for tissue regeneration.

Due to their high water content, hydrogels are highly attractive biomaterials for 3D printing as efficient ‘surrogates’ for the extracellular matrix, onto which cells can be cultured. However, while they are relatively easy to produce using a method called extrusion printing, their stability and structural integrity can weaken when they’re in contact with biological fluids or extracellular matrices.

The Biomaterials for Regenerative Therapies group’s new method uses a hybrid bioink that doesn’t need any photochemical or organic reagent and which safe for use in vivo. Using a versatile and biocompatible method called sol-gel, this bioink can be used to print a peptide-functionalized hydrogel. It’s the first time sol-gel has been used for hydrogel inks, as all examples combining sol-gel and 3D printing have so far dealt either with inorganic constructs or with extrusion printing under nonbiocompatible conditions.

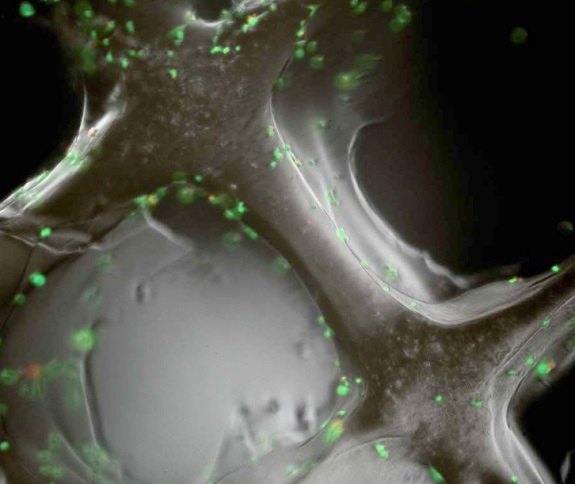

The new matrices work better than current ones because, as well as being biocompatible, certain essential processes such as hydrolysis occur during the printing process, resulting in a much stronger and more reliable structure. The researchers, who worked in collaboration with colleagues in France, were able to successfully seed them with mesenchymal stem cells, and are now looking at the possibility of encapsulating cells within the hybrid ink so that seeding can take place during the construction process.

As well as producing a stronger matrix, the combination of sol-gel chemistry and 3D printing means that the new method could be a promising way to quickly produce an unlimited number of customized, cell-laden, biocompatible structures. Not only that, but using several different hybrid bioinks could open the way to making multilayer and non-homogeneous biomaterials, mimicking the complexity of natural tissues even more closely.

The 3D scaffold fabrication was performed using the facilities of the platform of Production of Biomaterials and Biomolecules of the ICTS “NANBIOSIS”, more specifically by the U5 Unit of the CIBER in Bioengineering, Biomaterials & Nanomedicine (CIBER-BBN) at the Institute for Bioengineering of Catalonia (IBEC).

Article of reference: