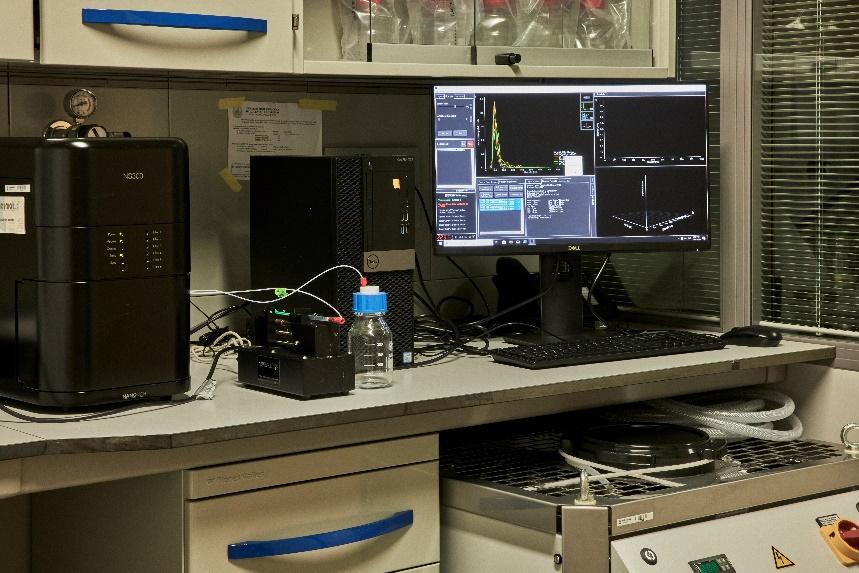

U9-E01. Reactor for laser-induced pyrolysis for controlled synthesis of nanoparticles

Reactor for laser-induced pyrolysis for controlled synthesis of nanoparticles from vapor phase precursors, aerosols and vaporized mixtures of gases and liquids. This reactor is composed of the following components:

•• Infrared CO2 laser resonator.

•• RF and DC three-phase radiofrequency supply at 360 and 440 V.

•• External cooler unit.

•• Laser power meter Unit by Ophir Optronics Ltd.

•• Reaction chamber for working under vacuum (10-6 mbar).

•• System for mixing and vaporization of gases and liquids to produce aerosol and gas mixtures at known compositions (Brooks Instrument).