U9-E05. Micromeritics ASA P 2020 analyzer

Micromeritics ASA P 2020 analyzer to measure the specific surface area and porosity of nanoparticles and nanostructures by gas adsorption.

Micromeritics ASA P 2020 analyzer to measure the specific surface area and porosity of nanoparticles and nanostructures by gas adsorption.

System for the thermal and optical characterization of core-shell metallic nanoparticles by surface plasmon resonance.

Software for data acquisition and processing from PCS , BET (for the interpretation of gas adsorption) and thermogravimetry.

This Unit offers the possibility of generating nanoparticle aerosols from a large variety of liquid suspensions or nanosized powders. Our patented technology allows a reliable aerosol generation from any preformed micro or nanoparticle powder. These aerosols with known and reproducible characteristics can then be used in wide variety of applications.

For determining the particle size and concentration in aerosol phase, several nanoparticle aerosol spectrometers are also available. These allow a real-time determination of the concentration of particulate matter in air streams and environments from sizes down to 5 nm.

Also, the Unit is able to identify nanosize matter from aerosols using a reliable, ultrasensitive identification in diverse matrices, based in introducing trace amounts of labels (eg. rare earth oxides or flurorophores).

The following devices are available through this service:

Customer benefits

This service is able to produce stable and reliable aerosol streams with nanoparticles of a large variety of origins, e.g., on exposure tests with environmental models or for development and validation of methods for sampling and monitoring of airborne matter.

Target customer

Researchers with interests in environmental modelling, nanoparticle aerosol distribution, pharmaceutical companies for aerosolized drug formulations, development of clinical aerosol formulations, testing of respiratory devices and research in filtering units.

Additional information

SEM and TEM images of the matter captured from the powder aerosol generator

Selected References:

Patents:

Conventional batch reactors may suffer from limitations due to the inefficient heat and mass transfer that makes it very difficult to achieve an accurate control on the synthesis conditions. This has a direct effect on key aspects such as reproducibility, selectivity and scalability. In fact, one of the bottlenecks in the development of Nanotechnology lies in the lack of precise synthesis methods capable of a scaled up production.

Continuous flow reactors based on microfluidic principles offer potential solutions to the aforementioned concerns. The exquisite control afforded by microfluidic reactors enables continuous production of nanomaterials with targeted sizes, shapes and composition. Moreover, the combination with microwave reactors can accelerate the stabilization of metastable phase due to the fast and selective heating supplied by this electromagnetic irradiation.

Customer benefits

The customer can benefit from the Unit´s expertise on the design of versatile microfluidic platforms to produce a broad library of nanostructures in a continuous fashion, often with a strong reduction of processing times with respect to the corresponding batch process. The Unit also offers unprecedented flexibility in terms of tuning the reaction atmosphere. Access to microwave reactors to perform fast heating reactions will be another asset to optimize specific synthesis and/or reactions in liquid media.

Target customer

Pharmaceutical companies, material suppliers, research groups pursuing a controlled and potentially scalable production of materials.

Additional information

Selected References:

The unit has access to different advanced characterization equipment including N2 adsorption (ASAP), porosimetry, several chromatography techniques (GC, HPLC, UPLC, GC-MS), Microwave Plasma-Atomic Emission Spectroscopy (MP-AES) for elemental analysis, UV-VIS spectroscopy, DSC, NTA, TPD/TPR and TGA. On the other hand, there is access to magnetic characterization by SQUID and VSM, Raman Spectroscopy (Alpha300R WITEC Raman confocal microscope), Infrared spectroscopy FTIR (Vertex 70 Bruker) and Fluorescence spectrometry (Perkin-Elmer, LS-45). Scanning Electron Microscopes (SEM) (including 3 dual-beam models); Transmission Electron Microscopes (TEM) (including two ultra-high resolution models with aberration corrector lens: TITAN 80-300 y TITAN CUBE 60-300). X-ray Diffractometers (specialized for powdered, low-angle and heating configurations), 2 X-ray Photoemission Spectrophotometers (XPS).

Customer benefits

The customer will be benefit from the expertise of the Unit´s members to carry out a complete characterization of nano and microstructured materials, ranging from polymeric, biological to inorganic compositions, including morphological, chemical, structural, optical, magnetic properties.

Target customer

Companies, material suppliers, pharma laboratories, research laboratories, conservation, medical laboratories.

Additional information

Selected Reference:

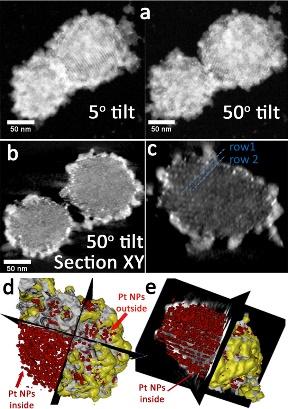

N. Miguel-Sancho, G. Martinez, V. Sebastian, A. Malumbres, I. Florea, R. Arenal, M. Carmen Ortega-Liebana, J.L. Hueso, J. Santamaria, Pumping Metallic Nanoparticles with Spatial Precision within Magnetic Mesoporous Platforms: 3D Characterization and Catalytic Application, Acs Applied Materials & Interfaces, 9 (2017) 41529-41536.

This facility is able to draw on a wide range of nanoparticles fabrication techniques by wet chemical approaches including the use of co-precipitation techniques, light-assisted co-deposition methods, hydrothermal, solvothermal synthesis. It also entails the use of alternative microfluidic reactors to achieve a higher control and reproducibility of targeted nanoparticles.

Customer benefits

The customers will benefit from the expertise of researchers to synthesize a wide variety of nanomaterials and nanocomposites including polymeric, magnetic, plasmonic, core-shell, nanorods, nanostars, nanoalloys of noble metal, transition metal and inorganic oxides. Microfluidic technology can be also designed to optimize specific demands of continuous production or in situ encapsulation of cargoes of interest.

Target customer

Companies, nanoparticle suppliers and research groups can benefit from custom-designed delivery of an ample portfolio of nanoparticle designs that can be applied in biomedicine, sensing, toxicology, delivery, decontamination and energy applications.

Additional information

Selected References:

Related Research Projects:

CADENCE – Catalytic Dual-Function Devices Against Cancer

09/2017 – 08/2022. Funding Entity: European Union H2020 – Advanced Grant. PI: Jesus Santamaria

The unit provides an automated system for the synthesis of nanoparticles using laser-induced pyrolysis of chemical precursors in gas and/or aerosol phase, which enables the generation of different type of nanoparticles. This service includes the possibility of selecting different feeding precursors either in gas, liquid or resuspended solids. The unit can also explore solid or liquid recollection of nanoparticles.

Customer benefits

This service can be quite convenient for generation of large quantities of magnetic or carbonaceous materials. It can be also ideal for custom-designed configurations of hybrid composites containing first and second transition metal oxides.

Target customer

This service is designed to supply nanoparticles for biomedical applications, including diagnosis and sensing. Research groups interested in generating large quantities for in vivo experiments, nanotoxicology or energy related applications are ideal customers.

Additional information

Selected References:

Selected Research Projects:

System for acidolactic cleavage of the peptide resin boundby anhydrous HF (Boc/Bzl strategy).