Tangential filtration Unit for purification.

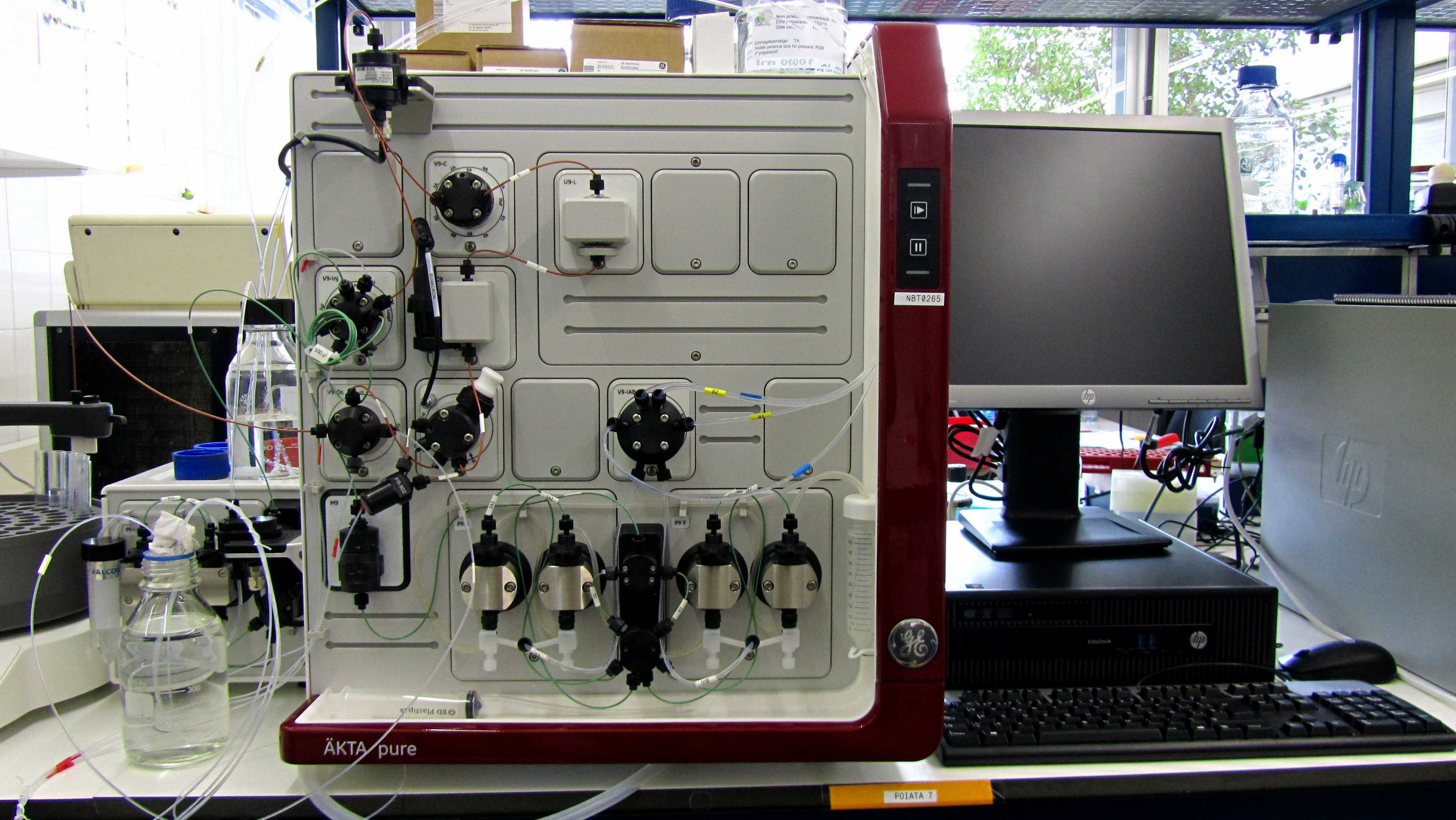

ÄKTA pure™ is a flexible and intuitive chromatography system for fast purification of proteins, peptides, and nucleic acids from microgram levels to tens of grams of target product.

ÄKTA pure™ chromatography system provides you with the following benefits:

• Modular system design with a large range of options to allow flexibility in purification of proteins and peptides

• Intuitive and flexible method creation, system control, and evaluation with UNICORN™ software

• Practical size, for easy placement on laboratory bench or in cold cabinet

• Reliable system with components and integrated

features based on the proven design of ÄKTA™ protein purification systems

• Predefined method settings for all our laboratory-scale chromatography columns

A double-door refrigerator (Unichromat 1500 HPLC cooling cabinet (UNIEQUIP) is available to contain FPLC-AKTA purification equipment inside, refrigerated, to be able to carry out low-temperature purifications of proteins that are sensitive to room temperature.

It also has a probe for acquiring temperature data from the refrigerator, to be able to track at all times the status of the samples that are stored inside the services during the protein production and purification service process and after

.

Incubator shaker with cooling unit for insect cells suspension cultures.

10 liter WAVE bioreactor for insect cells.

2 and 7 liter bioreactors for bio production

The PPP unit offers the oportunity to cryopreserve client samples under carefully controlled conditions using a temperature control system. This system notify us of any equipment malfunctions or temperature fluctuations that may affect the samples.

Customer benefits

For customers that don’t have equipment/space or control systems to store their samples adequately.

Target customer

The PPP Unit extends its services across the scientific community, serving both private and public research organizations. This includes support for research centres, universities, hospitals, and companies in the sector.

The PPP unit provides consultancy taking into acount specific issues covering cloning, recombinant protein production, and purification strategies.

The consultancy covers the entire design process for obtaining recombinant proteins according to specific needs, as well as troubleshooting solutions for achieving soluble and stable active proteins.

Examples of consultancy include:

Customer benefits

The PPP Unit specialises in designing, producing, and purifying recombinant proteins on demand, tailored to customers‘ requirements. We have an extensive expertise in designing different strategies to achieve succesfuly final products acccording to customers‘ needs. The service is completely personalised to ensure that the final product matches the intended use in terms of format, purity and activity.

Target customer

The PPP Unit extends its services across the scientific community, serving both private and public research organizations. This includes support for research centres, universities, hospitals, and companies in the sector. Leveraging our connection with the university, the PPP unit also provides specialised courses as part of the official master’s degrees and PhD programs at UAB.

The PPP Unit counts with a laboratory perfectly equipped for the purification of recombinant proteins. The protein purification procedure is carried out according the protein characteristics and customers‘ needs.

Design: identification of the most appropriate strategy for protein purification, given the physical and chemical properties, opting either for purification modules or, in the case of fusion proteins, elements which enable purification by affinity.

Protein purification: downstream processing using FPLC chromatography and/or tangential filtration either from the cellular pellet or the supernatant when the protein is secreted. When necessary, the purification is performed through solubilization of inclusion bodies or by purification under denaturing conditions with later refolding.

Final product: the purified protein is delivered in the buffer, temperature and the concentration requested by the costumer. When demanded, the protein can be delivered in lyophilised form.

Quality control: the purified recombinant protein is analysed in terms of molecular weight, purity by SDS-PAGE, aggregation by DLS and identification by Peptide-Mass Fingerprinting. Additional analysis can be performed under customer’s agreement such as buffer optimization (Microdyalisis) or freeze-thaw stability.

Customer benefits

The service is completely personalised to ensure that the final product matches the intended use in terms of format, purity and activity. We have various purification methodologies to address specific needs, offering a wide range of possibilities for obtaining the final product. All services adhere to standardised procedures, guaranteeing the quality of the end product. Thus, instead of offering a generic solution, we deliver a customised product with the exact specifications requested by the customer.

Target customer

The PPP Unit extends its services across the scientific community, serving both private and public research organizations. This includes support for research centres, universities, hospitals, and companies in the sector. Leveraging our connection with the university, the PPP unit also provides specialised courses as part of the official master’s degrees and PhD programs at UAB.

Additional information

Over its 17-year history, the PPP unit has successfully completed over 400 projects and has been recognised in more than 121 scientific publications. In the past three years, it has received citations in the following works:

The PPP Unit counts with a laboratory perfectly equipped for the bioproduction of recombinant proteins. The expression system is selected according to the protein characteristics and customer’s needs.

Transformation/transfection: the engineered construct is introduced inside the chosen expressing cells. In certain instances, involving insect expression, this step includes the isolation of a bacmid made for protein production via the baculovirus system.

Optimisation: selection of the optimal protein production conditions using small and medium-scale expression; confirmation of the protein expression using SDS-PAGE and Western blot analysis and quantification by densitometry. At this step protein solubility/aggregation is measured to obtain the best solubilizing conditions.

Recombinant protein production: scale-up of the upstream processing by batch culture according to the best protein production conditions selected during the optimization step.

Customer benefits

The service is completely personalised to ensure that the protein matches the intended use for later protein purification. Thus, instead of offering a generic solution, we deliver a customised product with the exact specifications and needs requested by the customer.

We have various expression systems to address specific needs, offering a wide range of possibilities for obtaining the final product. All services adhere to standardised procedures, guaranteeing the quality of the end product.

Target customer

The PPP Unit extends its services across the scientific community, serving both private and public research organizations. This includes support for research centres, universities, hospitals, and companies in the sector. Leveraging our connection with the university, the PPP unit also provides specialised courses as part of the official master’s degrees and PhD programs at UAB.

Additional information

Over its 17-year history, the PPP unit has successfully completed over 400 projects and has been recognised in more than 121 scientific publications. In the past three years, it has received citations in the following works:

Design: depending on the customers‘ needs and protein characteristics (size, modifications, etc.) we identify the most appropriate expression system for recombinant protein production selecting between Escherichia coli, insect cells (with expression systems based on transient expression or by infection with recombinant baculovirus ) and mammalian cells.

Cloning: the recombinant gene for the protein of interest, once optimised for codon usage, is cloned into the selected expression vector. When necessary, affinity purification tags, solubilizing tags and/or secreting signal peptides are incorporated into the design.

Sequencing: all constructs are sequenced to verify the accuracy of the gene sequence.

Customer benefits

The service is completely personalised to ensure that the final construct matches the intended use for later protein production in the chosen expression system and further purification. Thus, instead of offering a generic solution, we deliver a customised product with the exact specifications requested by the customer.

Target customer

This Unit extends its services across the scientific community, serving both private and public research organizations. This includes support for research centres, universities, hospitals, and companies in the sector. Leveraging our connection with the university, the PPP unit also provides specialised courses as part of the official master’s degrees and PhD programs at UAB.

Additional information

Over its 17-year history, this unit has successfully completed over 400 projects and has been recognised in more than 121 scientific publications. In the past three years, it has received citations in the following works: